Products

Overlay

The Nanoled plates, produced in a single hard welding layer are available in various thicknesses and hardfacing combinations. Nanoled overlay plates are supplied in chromium complex carbides, using an arc welding process open (open arc), totally protected to a carbon steel substrate (ASTM A36).

We evaluate the use in other substrates, according to the need of the application and according to the customer's project.

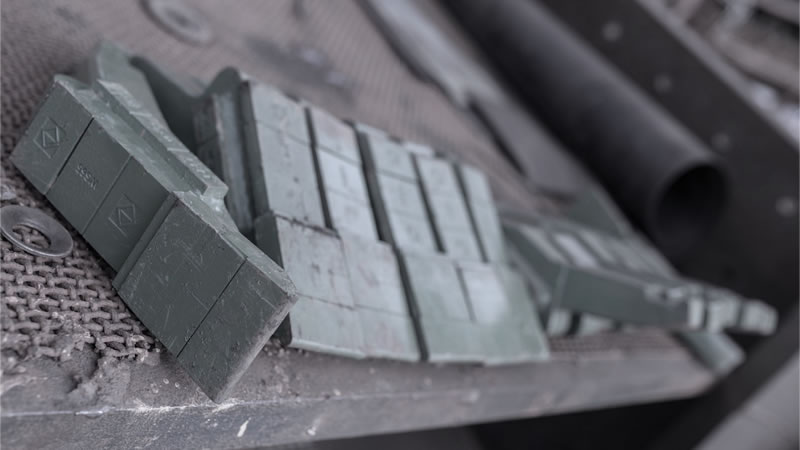

Wear Bars

Maximum protection against wear for your equipment. With low operating costs, Wear Bars are easy to bend, weld and have been developed for use in several industrial segments. The bars are produced from a special high-alloy with severe abrasion resistance and also against impact, with hardness of 700 HB (63HRc).

contact us

Steeldox

Steeldox 500 plates are tempered to 500HB surface hardness and its core is ductile, ideal for high impact. Produced with high technology oil quenching and rolling exclusive process (crossed). We produce homogeneous high quality hardness surface with extremely competitive cost. steeldox plates are indicated for moderate to high impact and abrasion phenomena.

contact usTungsten Carbide

Brazed tungsten carbide provide maximum availability life for plates and spare parts. It also improves inspection plan (low number of annual replacements) and consequently the safety of client's employees.

contact us

Ceramics

Nanoled provides all variations of this product to its customers, from plates in general, in any dimension, to pellets, cylinders, spheres and composite. Nanoled also supplies with the levels defined by its clients, which are 88 to 98% of Alumina, being product of stock, with 93% Alumina. In addition, it provides ceramics, according to client's design or need, developing applications and projects by its own professionals with extensive experience in the market segment.

contact us